Analysis Correlation

Correlation of FEA & CFD Analysis to Real-World Data

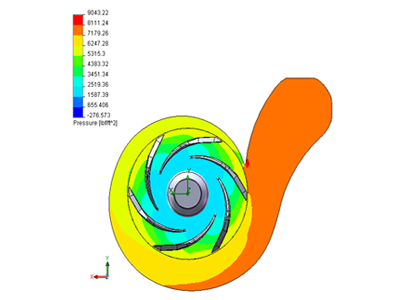

Centrifugal Pump – Testing Vs CFD Analysis Correlation

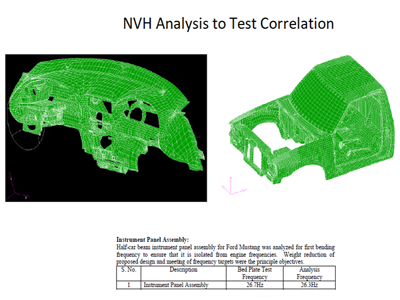

Noise Vibration Harshness – Testing & Correlation

Prediction of analytics from Finite Element Analysis as well as CFD Analysis needs to be verified against Experimental Data and/ or Real World Data. Establishes correct analysis procedures, better understanding of the physics of the simulation ,provides technological insight critical for product development.

EGS India has Vast Experience in Correlation Processes as well as establishment of FE and CFD Procedures for products. Wherin manufacturing organizations achieve indigenisation of technologies and establish know-how for products – the real wealth of any organisation that is involved in product design and development.

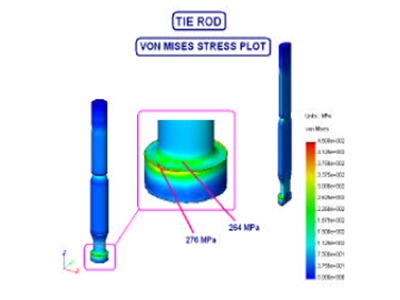

Strain Gage Correlation – Tie Rod Under Tensile Loading

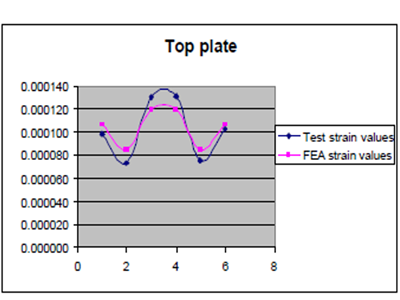

| Strain Correlation | Deflection Validation |

| Frequency – Modal Assurance Criteria | Point Mobility Evaluation |

| Temperature Correlation | Fluid Flow Parameters such as Pressure Drop,Free Stream Velocity and Mass Flow Rates |

| Efficiency of Pumps, Heat Exchangers | Life Prediction |

| Fluid Induced Vibrations – Correlation to Observed Data | Elastomeric Deflections and Deformed Shape Correlation |

| High Cycle Fatigue – Correlation to test | Warranty: Service Life calculation for Equipments |

| Thermal Expansion | Buckling Load Characterisation and Identification of Influencing Co-efficients |

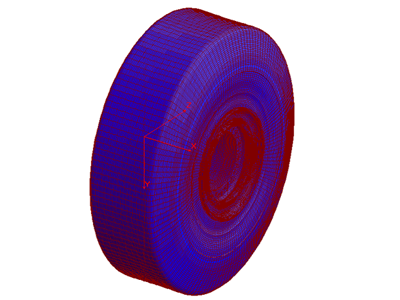

Wheel Strain Gage Testing and Corrlation

Benefits:

Technological Know-How

Increased Reliability

Improved Simulation Process

Reduction in Test Prototypes

Why EGS India?

EGS India has been performing Correlations between Analytical Estimations and Test Data, for partners ,delivering on procedures and inferences,Knowledge of Finite Element Analysis and CFD Analysis Procedures and Methods Capability to identify and establish dimensional correlations between Design Manufacturing Variance Models for Higher level of prediction and acceptability Established process for correlation proven capabilities in Field failure replication and elimination.

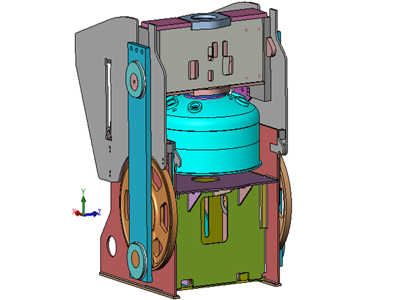

Press Deflection Correlation – Simulation Vs Load Cell

Comments are closed.