Tool Design

EGS India – Value Added Reseller (VAR) of SOLIDWORKS in

Chennai, Coimbatore, Trichy & India

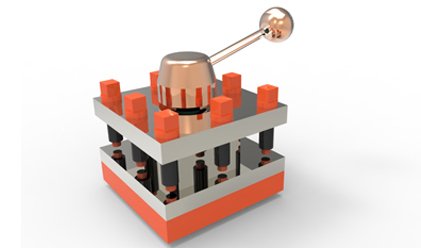

Benefits of SOLIDWORKS for Tool Design

- Design of Dies and Tool Sets for Plastic/ Sheet-metal/ Casting/ Forging Components.

- Integrated FEA for Tool Stress Analysis.

- Tolerance Analysis in 3D.

- Inter-operability with other CAD systems – Pro/Engineer, CATIA, Unigraphics, SDRC IDEAS, Parasolid among others.

- Ability to model complex surfaces.

- E-drawings: Communicate 2D and 3D Designs – for SOLIDWORKS, Pro/Engineer, AutoCAD, DWG and DXF.

- Customized Menu Interface for Mould and Tool Die Designs.

- Eliminate Re-work.

- Surface Quality Checks for accurate Die Designs.

Special Toolset for Mould and Tood Design

Industry Specific Interface

Draft Analysis

Parting Surface Development

Curvature Continuity Checks

Direct Benefits using SOLIDWORKS – Customer Feedback

- Compressed mold development cycles.

- Added mold development and draft analysis capabilities.

- Generated new customers.

- Improved competitive position.

- Saved time in the design process by reusing existing design material without any problems.

- Facilitated smooth transfer of design data to workshop.

- Realized an outstanding price/performance ratio.

- Benefited designers quickly because of ease of use.

- Realized better understanding of the design.

- Realized complete freedom in generating sections, in order to make undercuts more visible.

- Integrated CAD with CAMWorks for NC programming and MoldWorks for mold-making analysis.

- Enjoyed the ability to use more affordable hardware.

Why BUY SOLIDWORKS, for Mould Tool and Die Design, from EGS India,

Chennai / Coimbatore / Trichy?

- Hands-on training on Mould, Tool and Die Designs based on Customer Projects – Direct Business Impact in successful implementation.

- SWATT – SOLIDWORKS Authorized Testing, and Training Centre.

- Proven Experience in Design and Development – Emphasis on Design For Manufacture (DFM).

- Imparting innovative design processes and best practices to accelerate die design and development.

- Critical knowledge on GD&T – Requirement of Industry for Quality and Cost considerations.

Why BUY SOLIDWORKS, for Mould Tool and Die Design, from EGS India,

Chennai / Coimbatore / Trichy?

FAQs IN MOLD INDUSTRY

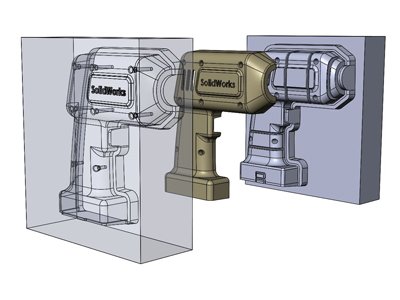

SOLIDWORKS has tools and commands specific for Mold designing for core and cavity splitting. You can create a mold using a sequence of integrated tools that control the mold-creation process.

No. SOLIDWORKS 3D CAD has inbuilt capabilities for Mold tool designs which are included in the standard module itself.

Yes. Other 3D CAD and Neutral Files like STEP, IGES, and Parasolid files can also be imported into SOLIDWORKS and can be used for Mold Splitting.

SOLIDWORKS has import diagnostic tools to repair imported models. Import diagnostics repair faulty surfaces knit repaired surfaces into closed bodies and make closed bodies into solids.

SOLIDWORKS is efficiently used in various mold, pattern makers, casting, tool, and dies industries for materials such as Steel, Aluminium, Copper, Metal alloys, Rubber, Plastics, and more. It can also be used in industries for pattern making, Die and Sand Casings, and Investment castings.

Comments are closed.