Vibration FEA

Vibration & Structural Dynamics – Benefits to Customers

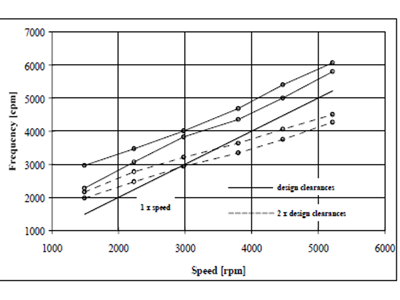

Rotodynamic Analysis of Impeller Shaft

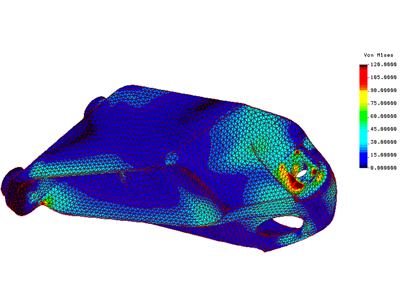

Compressor Blade Vibration Analysis

EGS India has successfuly addressed problems relating to vibrations in wide-ranging areas of applications including Machine Tool, Automotive NVH, Process Equipments, Rotating Equipments, Material Handling Systems, Earthquake Engineering and Foundation Dynamis to name a few.

Customer Benefits include :

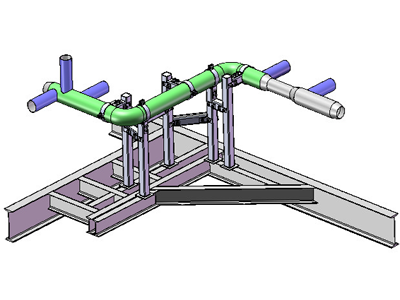

Titanium Piping Vibration Analysis

- Elimination of Failures due to Vibrations

- Improved Product Performance: Root-Cause Analysis leading to solutions for System-level issues and problems

- Accelerated Durability Life Prediction: Improved Reliability

Vibration FEA – Experience of EGS India

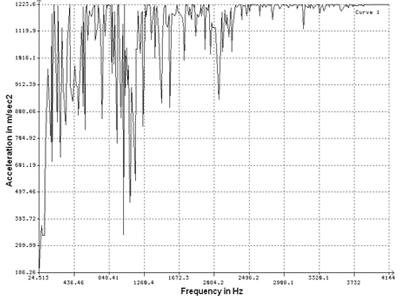

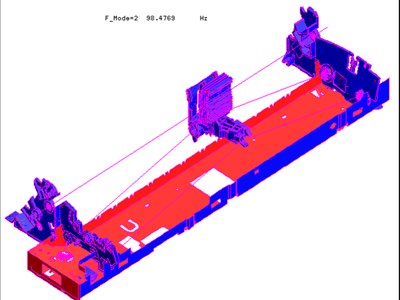

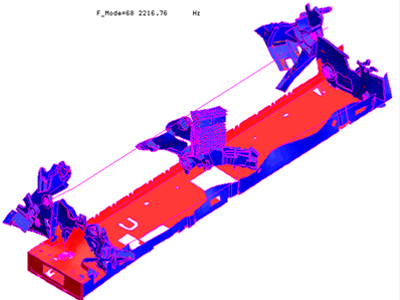

EGS India has solved numerous problems involving vibrations of equipments, automotive systems and machines among others. From harmonic excitations to random responses, EGS India has worked on Vibrations and Structural Dynamic Problems on full systems to predict, identify and alleviate cause of vibrations leading to improved durability and reliability.

Some of the projects done by us in Vibrations using FEA include the following:

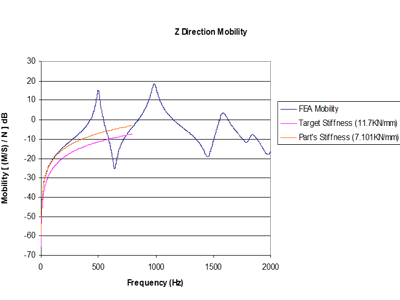

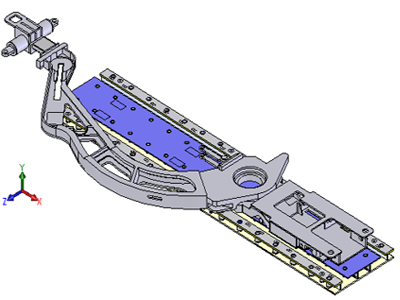

Engine Mount – Point Mobility Test Simulation

- Prediction of vehicle responses due to engine excitation

- High-speed Test Rigs: Prediction of vulnerable frequencies

- Wheel Dynamics & NVH

- Engine Mount Design to achieve Point Mobility & Dynamic Stiffness Targets

- Fluid Induced Vibrations of process equipments

- Response of Compressor foundation to harmonic excitations

- Elimination of Seal/ Bearing Assembly Failure due to vibrations in Water Pump

- Rotor Dynamic Calculations to predict Torsional Vibrations in multi-rotor systems

- Analysis-to-test correlations for frequencies & responses

Comments are closed.