Sheet Metal

EGS India – Value Added Reseller (VAR) of SOLIDWORKS in Chennai, Coimbatore, Trichy, India Delivering Design Technology since 1993

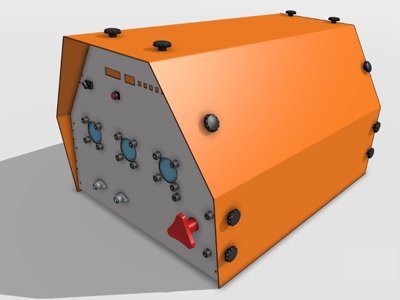

SOLIDWORKS – Benefits for Sheet-metal Design

-

- Advanced Features for Sheet Metal Design

-

- Interactive Design of of Sheet Metal Surfaces

-

- Bend Factor Calculations

-

- Ability to visualize, check and validate Design Concepts in 3D

-

- Production-ready Bi-Directinal Parametric 2D Drawings that update automatically with Design Changes

-

- Communicate 2D and 3D Designs using e-Drawings – for SOLIDWORKS, DWG and DXF

-

- Library Sketches, Features, Forming Tools, Parts, Assemblies for Drag-and-Drop

-

- Accurate estimate of Blank requirement

-

- Improve Reliability by performing FEA using Cosmos inside SOLIDWORKS – No Translation of design data

Special Toolsets for Sheet-metal Design

-

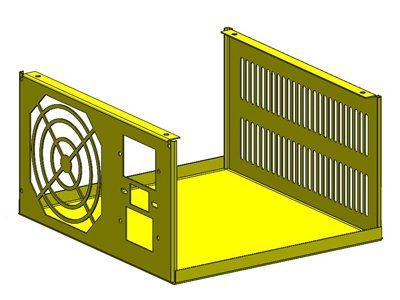

- Rich Sheet-metal Features

-

- Variety of Corner Treatment

-

- Forming Tools

-

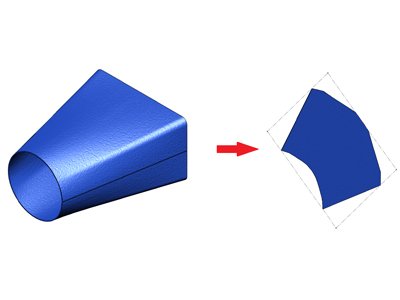

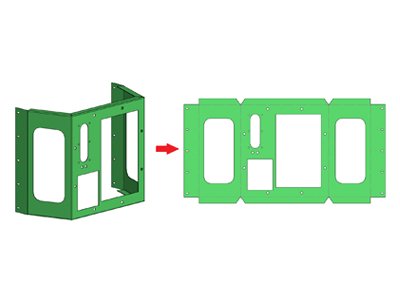

- Blank Development for regular sheet metal parts

-

- Bend Control Parameters

-

- Flange Operations

-

- Automatic Relief Cuts

Applications of SOLIDWORKS in Sheet-metal Design

-

- Progressive Die Designs

-

- Dies for Sheet-metal parts with complex shapes

-

- Automation of Die designs for sheet-metal parts using SOLIDWORKS API

Salient Features of SOLIDWORKS Sheet metal design

-

- Design a Part from the Flattened State and then Convert it to Sheet Metal

-

- Design a Sheet Metal Part from the Flattened State

-

- Design a Part from a Solid, then Convert it to Sheet Metal

-

- Design a Sheet Metal Part from a Solid

-

- Advanced Corner treatment

-

- Lofted Bend with rich options for users

-

- Add weld bead to corner of sheet-metal parts

-

- Forming Tools from Design Library for different shapes

-

- Recognize uniform thickness regular sheet-metal parts from imported CAD data such as Pro/Engineer, SDRC IDEAS, CATIA, AutoCAD Inventor, Unigraphics among others

-

- Create sheet-metal gauge table

-

- Variety of Tabs, Flanges and hems

Why BUY SOLIDWORKS, for Sheet-metal Design, from EGS India, Chennai / Coimbatore?

-

- Proven Technical support with large number of satisfied customers in Design using SOLIDWORKS in Production

-

- SWATT – SOLIDWORKS Authorized Testing, and Training Centre

-

- Proven Experience in Working with Sheet-Metal Companies, Progressive Sheet Metal Die Designs

-

- Domain knowledge and implementation of Best Design Practice as a part of training program

-

- Specialists in Design Automation of Sheet Metal Drawings using VBA & GD and T

Purchase SOLIDWORKS in India by investing with the right partner – EGS India :

Comments are closed.