Power

Remain Life Analysis (RLA), Thermal Management of Power Equipements using SOLIDWORKS Simulation – Sales and Technical Support in India since 1997

SOLIDWORKS Simulation has been widely used in the power industry to study efficiency of sub-systems involved in power generation. Combination of what-if scenarios can be studied with ease to understand system response and enhance reliability. Following functionalities have benefited the Power Sector immensely:

- Remaining Life Analysis of Static and Rotating components such as turbine parts

- Heat transfer analysis of heat exchangers, boilers, pre-heaters, headers among others.

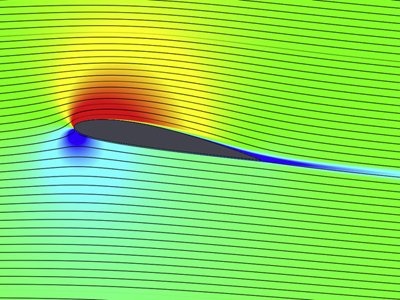

- Fluid flow analysis in cyclones, waste-heat recovery systems, chimneys, cooling towers and environmental and pollution control sub-systems

- Efficiency estimation of pumps

- Energy flow studies in wind power applications

- Solutions to Vibration induced failure problems

- Strength and stiffness calculations for pressure vessels, structural members and tanks

- Earthquake Response (Seismic) Analysis of sub-systems

- Creep analysis and aging calculations for high-temperature applications

Advantages of SOLIDWORKS Simulation for Power Applications

- Wide range of Analysis – From components to Sub-systems to Full Systems

- Kinematic Analysis using Cosmos Motion for mechanisms such Dampers and Gear-box

- Life Estimation of rotating components – High Cycle Fatigue

- Weight reduction of Wind-mill sub-systems such as nacelle frames, hub, extenders, support structures

- Heat Transfer efficiency prediction in heat exchangers, condensers, chillers among other systems

- Rotor-dynamic calculations

Comments are closed.