Material Definition

The material definition can be one of the most uncertain components of a model, yet it is critical because it affects the performance of any design followed by simulation.

Material Calibration

An accurate depiction of material behavior is required for realistic simulation. Each material’s micro-structure causes it to behave differently when loaded or unloaded.

In finite element analysis, equations are used to capture the behavior of materials. The material reaction is specified by one or more factors based on material representation settings. The fit of the mathematical model to the test data is determined by both equations and parameters.

Engineering Materials & Material Behaviour

It is important to distinguish between engineering material and material behavior.

Engineering Materials:

- Metals

- Plastics

- Rubbers

- Composites

- Concrete & Geo-materials & etc…

Material behavior:

Material model data based on material behavior is necessary for engineering analysis. As a result, the approximation is performed using material behavior data.

General Properties (Damping, Density, Thermal Expansion)

Elastic material Properties

Thermal Properties

Acoustic Properties

Hydrostatic Fluid Properties & etc…

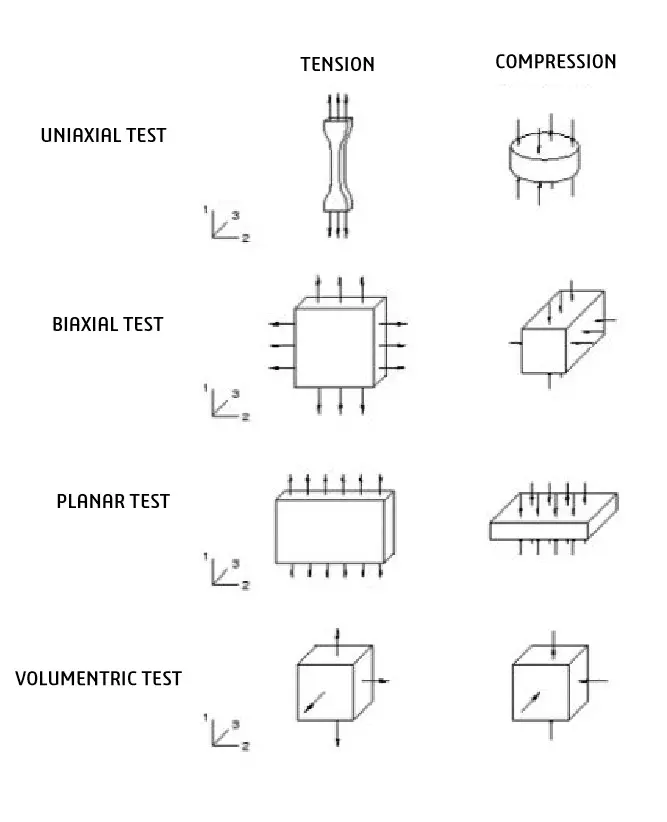

Experimental test data:

- Before picking a material model, consider the aims of the study, the nature of the loading, and the available test data.

- For Example, if the simulation is based on the performance of the paper clip a “linear model” is probably sufficient.

- However, if the simulation is carried out to understand or improve the manufacturing process of the paper clip a “Non-Linear model” is required.

Note: Same Paper clip, same material but completely different material behavior.

(In the next blog the material calibration in SIMULIA 3DEXPERIENCE Platform/Abaqus will be discussed.)